Whether these words come from General Omar Bradley or General Norman Schwartzkopf (opinions vary), their message is clear. And when it comes to the Australian Army’s huge investment in armoured vehicles, it’s time to move on from talking about constructing them to who will service them and where.

Policy makers should acknowledge that while vehicle construction in the south of Australia is locked in, logistics support must be set up in the north.

Acquisition of heavy armoured vehicles is the Australian Army’s greatest replacement effort in two generations. The current fleet of M1A1 tanks, ASLAV wheeled fighting vehicles and venerable M113 armoured personnel carriers will soon find new homes at clubs of the Returned Services League—or storage for reactivation in time of dire need. M1A2 SEPv3 tanks, Redback infantry fighting vehicles and Boxer combat reconnaissance vehicles will be the new arsenal, with K9 self-propelled howitzers a noteworthy addition in the near future.

The government has said who will supply these vehicles and where they will be assembled. Hanwha’s Redbacks and K9s will be assembled in Geelong, and Rheinmetall’s Boxers in Ipswich, while General Dynamics’ M1A2s will come directly from the United States.

But while the new fleet will be produced in the south, it will be employed in the north.

Except for a few training platforms, every armoured vehicle in the Australian Army will be allocated to the 3rd Brigade, based in Townsville, making it the most potent fighting formation in the region. As any logistician will attest, this power comes with a cost. There will be close to 300 vehicles, all thirsty for fuel, hungry for ammunition, and worthless without spare parts, maintenance schedules and overhaul facilities.

There are several ways to provide this logistics support, although the government has not yet formally announced which one it favours. The vehicles can either return to their points of manufacture for deeper maintenance, or they can be supported locally—and that would be the best choice.

Returning vehicles to their factories has advantages. Turning a production assembly line into a suitably equipped maintenance line would be relatively inexpensive. The people who assembled the vehicles would have the expertise to maintain and overhaul them. Arguably, this strategy would provide an affordable means to ensure the army’s fighting vehicles are safe, effective and sustainable. It certainly sounds reasonable, and may be very palatable for Defence Minister Richard Marles, whose seat of Corio includes Geelong. It is not, however, the option that logistics professionals would advocate.

The vehicles will be based far from their factories. It is 2500km from Townsville to Geelong by the fastest route and 3200km via the National Highway. Regularly transporting vehicles that weigh 40 to 70 tonnes over such continental distances is an immense undertaking, requiring specialist trailers and complicated by oversize vehicle regulations. The volume of fuel consumed by M1s would pale would hardly compare to the amount needed by the fleet of prime movers hauling them and other armoured vehicles across the country. Carbon dioxide emissions would be correspondingly higher.

Crucially, the transit would add weeks to each overhaul, drastically reducing the availability of the fleet and limiting training time.

Under these circumstances, any logistician would prefer a reasonable and suitable way to provide maintenance close to where the vehicles were used.

Northern Queensland has the facilities and expertise for this. Dean Deighton of Australian Industry Group notes that the region has the capacity and capability to establish and operate maintenance, engineering and logistics support facilities, and that doing the work there is highly likely to be least expensive. The region already supports heavy vehicles of many makes in the resources industry, particularly in the cities of Mackay, Townsville and more recently Cairns. Widening its scope to include the army’s new vehicles would leverage these existing skills and bring welcome investment.

Indeed, the army and one of its aircraft suppliers have already set a precedent: Boeing Defence Australia will support the army’s Chinook and Apache helicopters from Townsville, with deeper maintenance done at the location where the aircraft are operated. Hanwha, General Dynamics and Rheinmetall could establish similar facilities in northern Queensland so that maintenance support would be timely, inexpensive and effective.

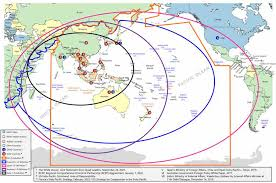

A regional maintenance hub would also offer expanded business opportunities. Lockheed Martin and Boeing have recently approved Australian subsidiaries performing maintenance for aircraft of other countries. Similarly, a regional armoured vehicle maintenance hub could provide local maintenance to visiting defence forces so that their vehicles stationed in Townsville Field Training Area, Shoalwater Bay and other locations remain ready to fight at a moment’s notice. This would demonstrate Australia’s reliability as a partner of choice and strategic point of departure for regional operations, as well as meeting the needs of national strategy and local logistics.

The advantages are far too great to ignore. Australia’s vehicles will be operated in the north, and that’s where they should be maintained.